Below are some projects executed by us and appreciated by our satisfied customers.

Comprehensive overhauling services for your MV/HV Electrical Motors and Generators covering conventional cleaning, safe and effective dry-ice cleaning, backed up by diagnostic assessment and verification of our services.

Resolving high temperature issue due to oil contamination

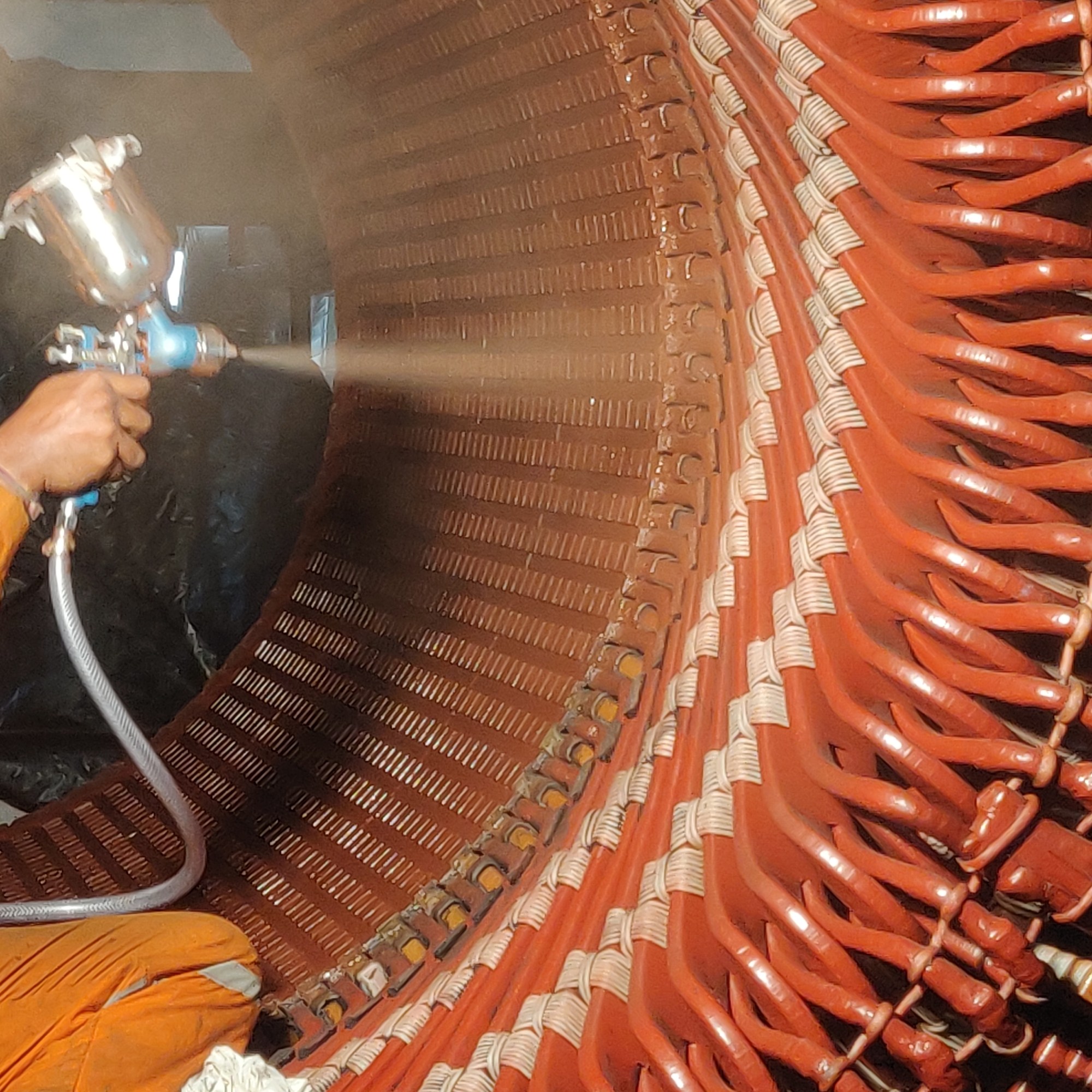

Capital outage was planned for a 37.5 MVA, 11 kV, 1500 rpm generator due to high temperatures. The stator and rotor had excessive oil and dust contamination. AEE team carried out cleaning methodically using solvents for pre-cleaning followed by cryogenic cleaning using dry-ice at controlled pressure. After drying out and confirming the improvements in the Insulation Resistance and Polarization Index values, stator/rotor/exciter was varnished. This also led to lowering of operating temperatures and hence improved reliability.

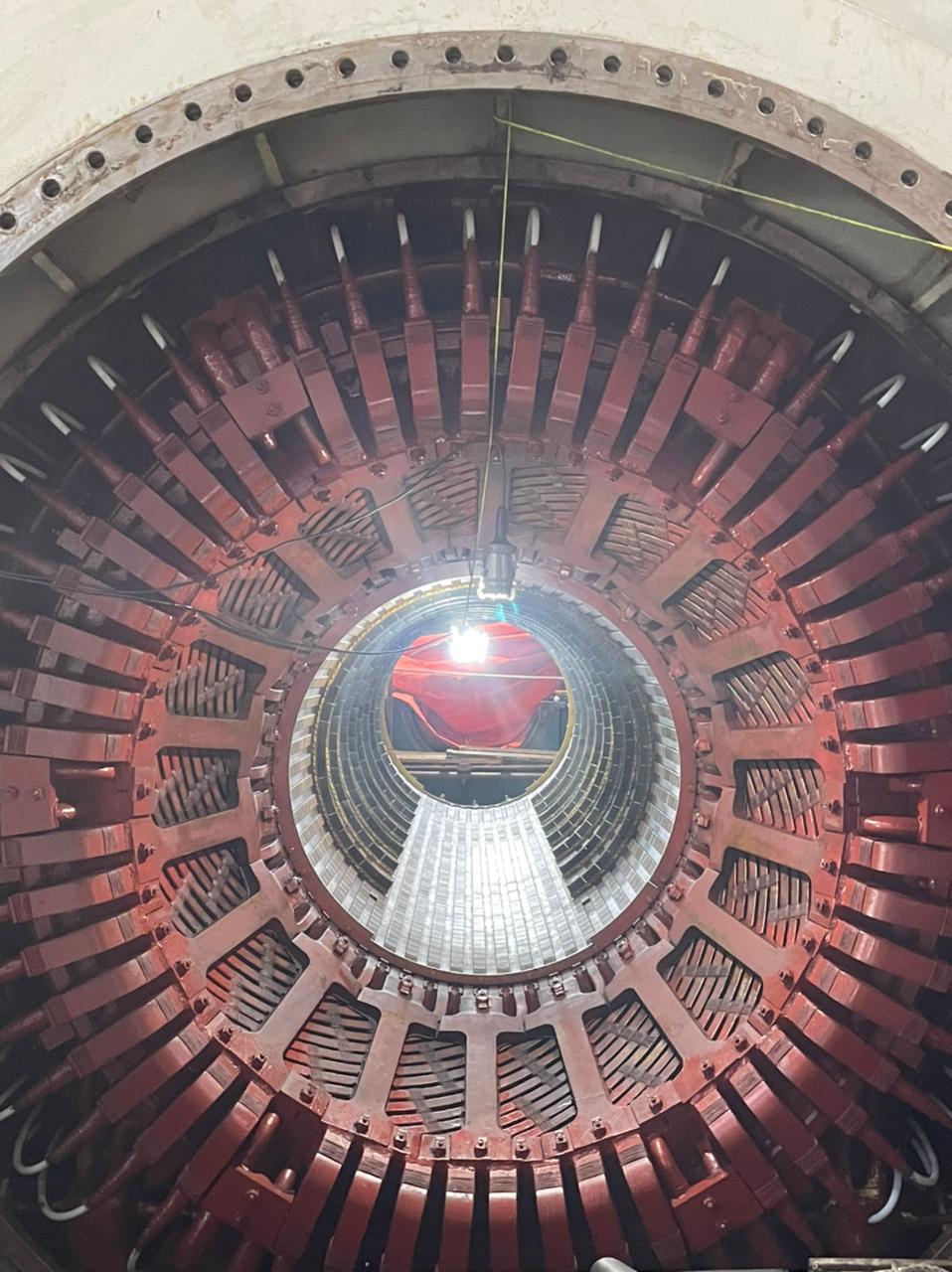

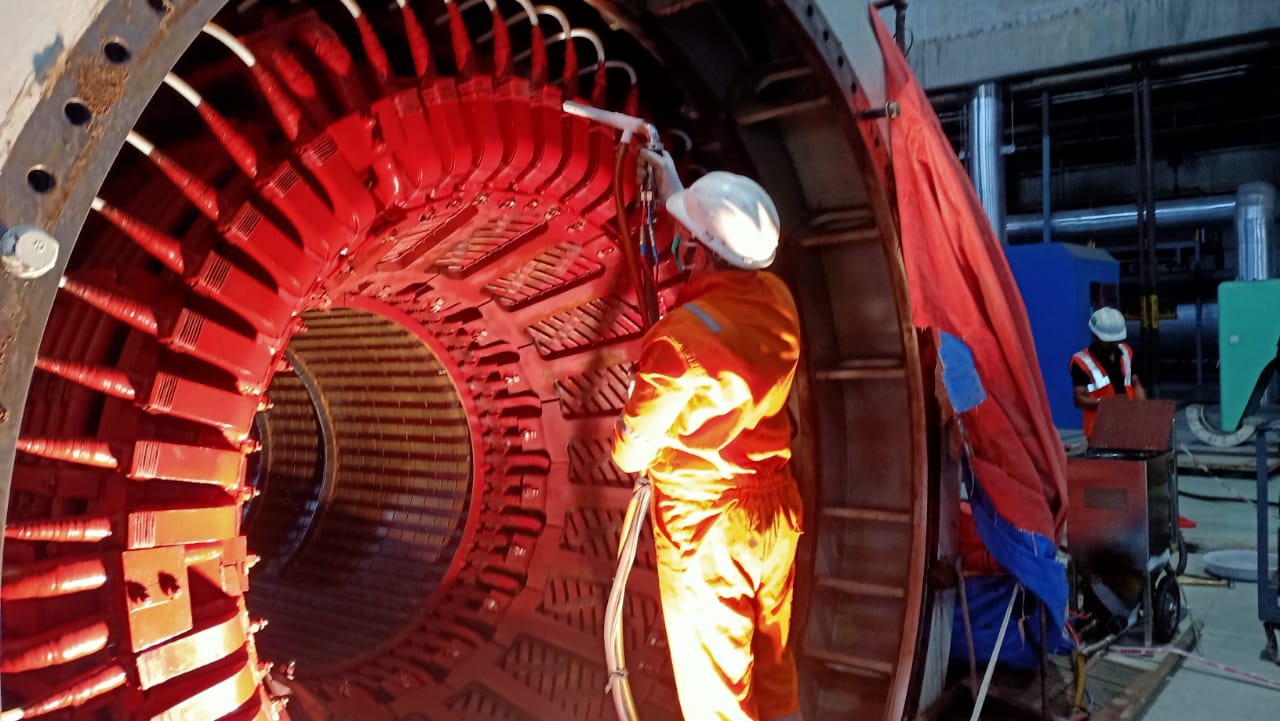

360 MW Generator Overhaul

360 MW, 20 kV, 12 kA, 3000 rpm stator and rotor of a water-cooled generator was under outage to rectify a rotor fan blade issue. AEE team got into swift action to remove contaminants (oil dust and metallic particles) by thorough cleaning using vacuum, dry-ice cleaning and subsequent varnishing.

110 MW Generator Overhaul

110 MW, 11 kV, 7.3 kA, 3000 rpm stator and rotor of an air-cooled generator was under outage. Electrical RLA tests indicated high winding resistance in one phase causing unbalance. Significant carbon dust was observed between terminal and busbar. The area was cleaned thoroughly. IR values were in MOhm range. AEE team observed dry dust type contaminants, cracks in surface varnish paint and surface partial discharges. AEE conducted overhaul using dry-ice cleaning, heating and subsequent varnishing. IR values improved to GOhm range and PD level dropped significantly. RSO tests indicated no anomaly in rotor windings. Timely action helped in improved reliability and life extension

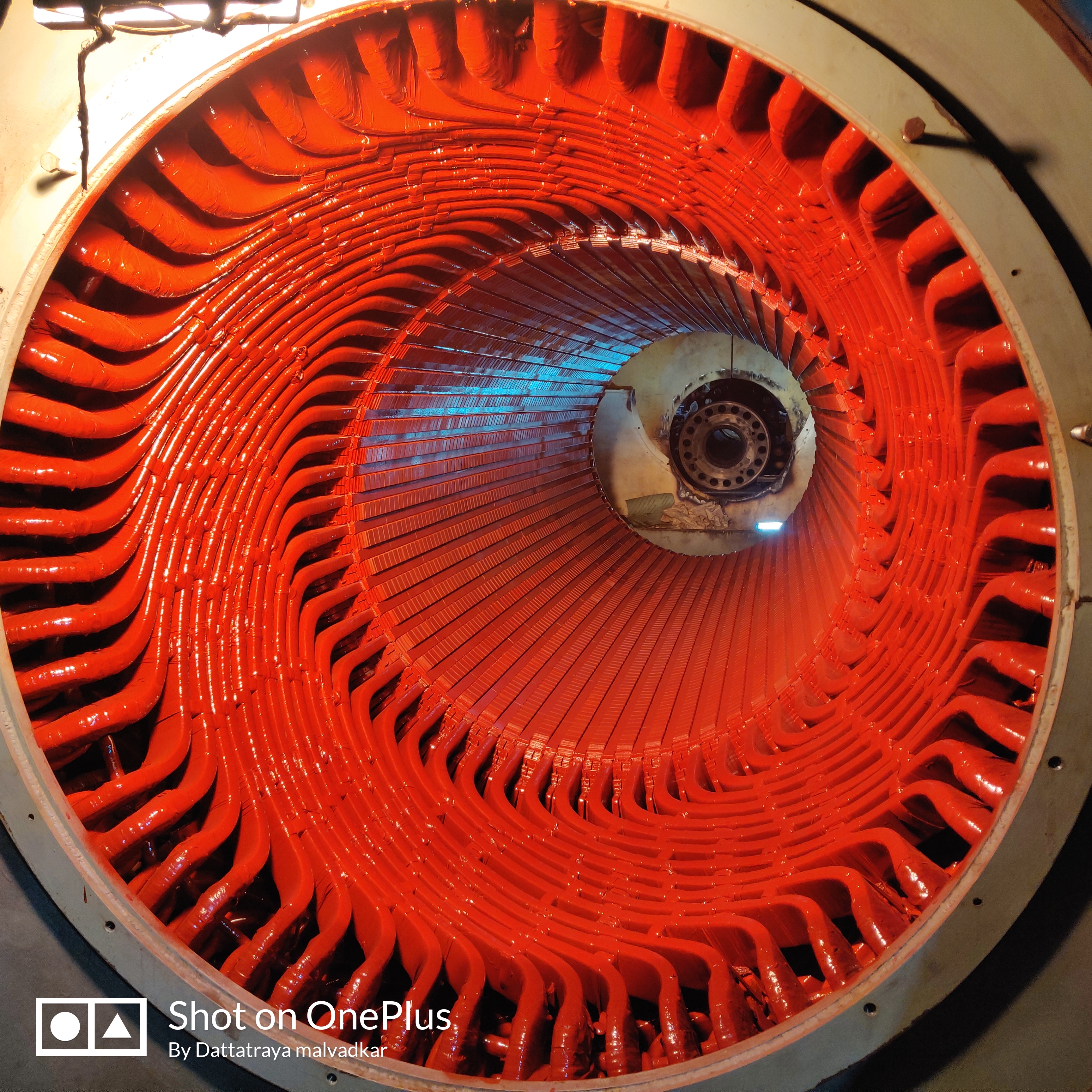

30 MW Planned Capital Outage

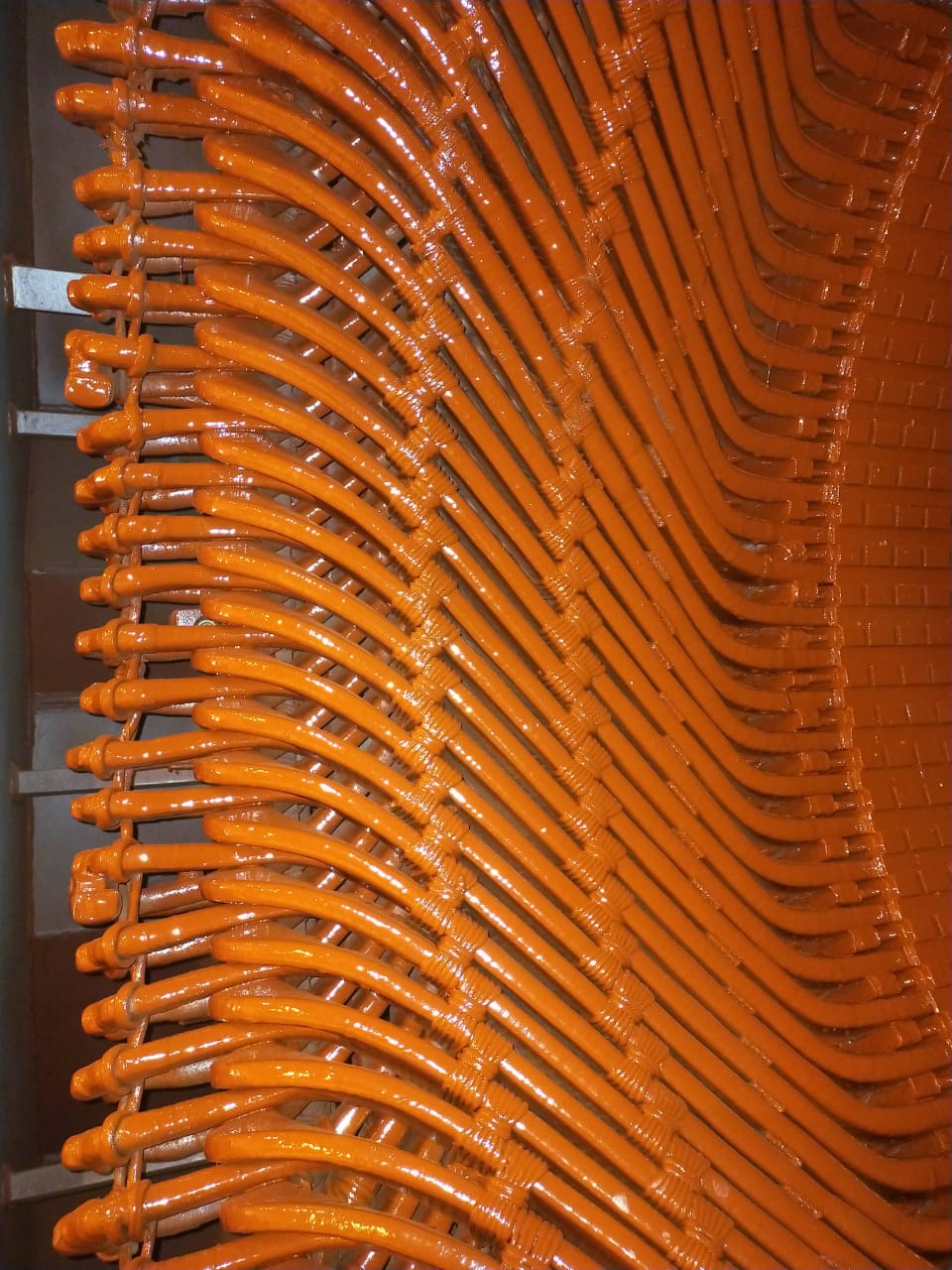

30 MW, 11 kV, 1500 rpm stator and rotor of a generator was under planned outage. AEE conducted overhaul using dry-ice cleaning, heating and subsequent varnishing. The condition of overhangs before and after overhauling is as shown

Of course we can go on and on with our several projects and case studies. For your planned motor and generator outages, contact us on +91 98921 25721.

Note that with top-class condition assessment services, we also help you classify your large fleet of motors into ones that need immediate action and those that can be deferred for next outage, further saving you downtime and budget.